The automotive industry is increasingly adopting composite material replacement due to their superior strength, durability, and weight reduction capabilities, leading to improved fuel efficiency and enhanced safety features. While initially used in high-performance cars, composites are now becoming more accessible for mainstream car body repair and bodywork applications. This shift offers significant environmental benefits by reducing vehicle weight and carbon emissions, along with economic advantages through streamlined repair processes, lower labor costs, and faster turnaround times. Composite material replacement presents a sustainable and cost-effective solution for auto repairs, revolutionizing the industry.

The automotive industry is experiencing a paradigm shift with the increasing adoption of composite materials for vehicle construction. This article explores the future of composite material replacement in auto repairs, delving into their current benefits, environmental advantages, and challenges compared to traditional methods. We examine cutting-edge technologies such as 3D printing and advanced composites, highlighting innovations that promise enhanced efficiency, cost-effectiveness, and sustainability in damage restoration.

- The Rise of Composite Materials in Automotive Industry

- – Current state and benefits of composite materials in car manufacturing

- – Environmental impact and economic advantages

The Rise of Composite Materials in Automotive Industry

The automotive industry has witnessed a significant shift towards composite materials for various components, revolutionizing both vehicle performance and manufacturing processes. Composite material replacement is no longer a novelty but a growing trend, primarily due to their exceptional strength-to-weight ratio, durability, and ability to reduce vehicle weight, leading to improved fuel efficiency. These materials, composed of a matrix (often a resin) reinforced with fibers like carbon or glass, offer superior structural integrity compared to traditional metals in auto bodywork. Their lightweight nature is especially advantageous in today’s market, where manufacturers strive to meet stringent emissions standards while enhancing safety features.

The adoption of composite materials has been gradual but steady, starting from high-performance sports cars to more mainstream vehicles. As technology advances, these materials are becoming increasingly accessible and cost-effective for widespread use in car body repair and auto bodywork applications. Their versatility allows them to be molded into complex shapes, enabling designers to create sleek, aerodynamic profiles while ensuring structural integrity. With the continuous development of composite technologies, the future looks bright for their integration into vehicle construction, further pushing the boundaries of what’s possible in car body repair and overall auto bodywork solutions.

– Current state and benefits of composite materials in car manufacturing

Composite materials have revolutionized car manufacturing, offering lightweight yet robust alternatives to traditional metals. Their widespread adoption is driven by the automotive industry’s push for fuel efficiency and improved performance. In modern vehicles, composite materials are used extensively in bodies, interiors, and even engine components due to their superior strength-to-weight ratio and resistance to corrosion. This shift has not only enhanced vehicle performance but also contributed to reduced environmental impact during production.

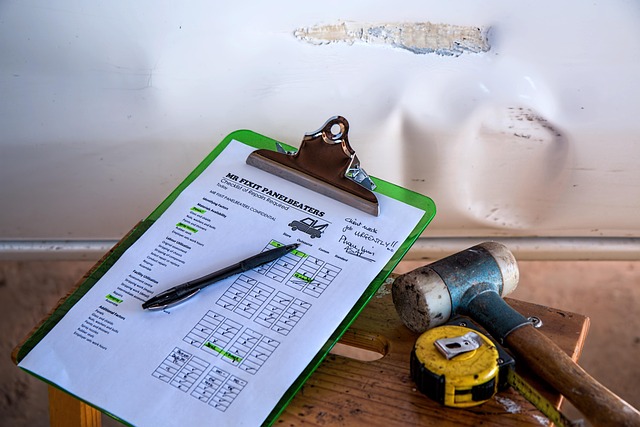

As the focus on sustainability intensifies, the exploration of composite material replacement in auto repairs is gaining traction. Traditional metal repairs often involve intensive labor and significant waste generation. Composite material replacements, however, offer a more eco-friendly approach by reducing the need for extensive welding, painting, and finishing processes typically associated with auto repair shops. This not only minimizes environmental impact but also streamlines car restoration processes, making them more efficient and cost-effective.

– Environmental impact and economic advantages

The shift towards composite material replacement in auto repairs offers significant environmental and economic benefits. Composite materials, known for their lightweight properties, reduce overall vehicle weight, leading to decreased fuel consumption and lower carbon emissions. This is particularly crucial in the context of sustainability as the automotive industry contributes substantially to global greenhouse gas levels.

From an economic perspective, composite material replacement can streamline auto glass repair and car body restoration processes. Traditional metal components often require intensive manufacturing and repair methods, consuming more resources and adding to labor costs. Composites, however, can be molded and repaired with greater efficiency, reducing waste and labor expenses in automotive body shops. This not only makes repairs more cost-effective but also accelerates turnaround times, benefiting both customers and businesses alike.

As the automotive industry continues to evolve, the future of composite material replacement in auto repairs looks promising. With advancements in technology and increasing environmental awareness, these materials offer a sustainable and cost-effective alternative to traditional parts. By embracing composite material replacements, the industry can reduce weight, enhance performance, and minimize its carbon footprint, paving the way for a greener and more efficient future on the road.